Blog

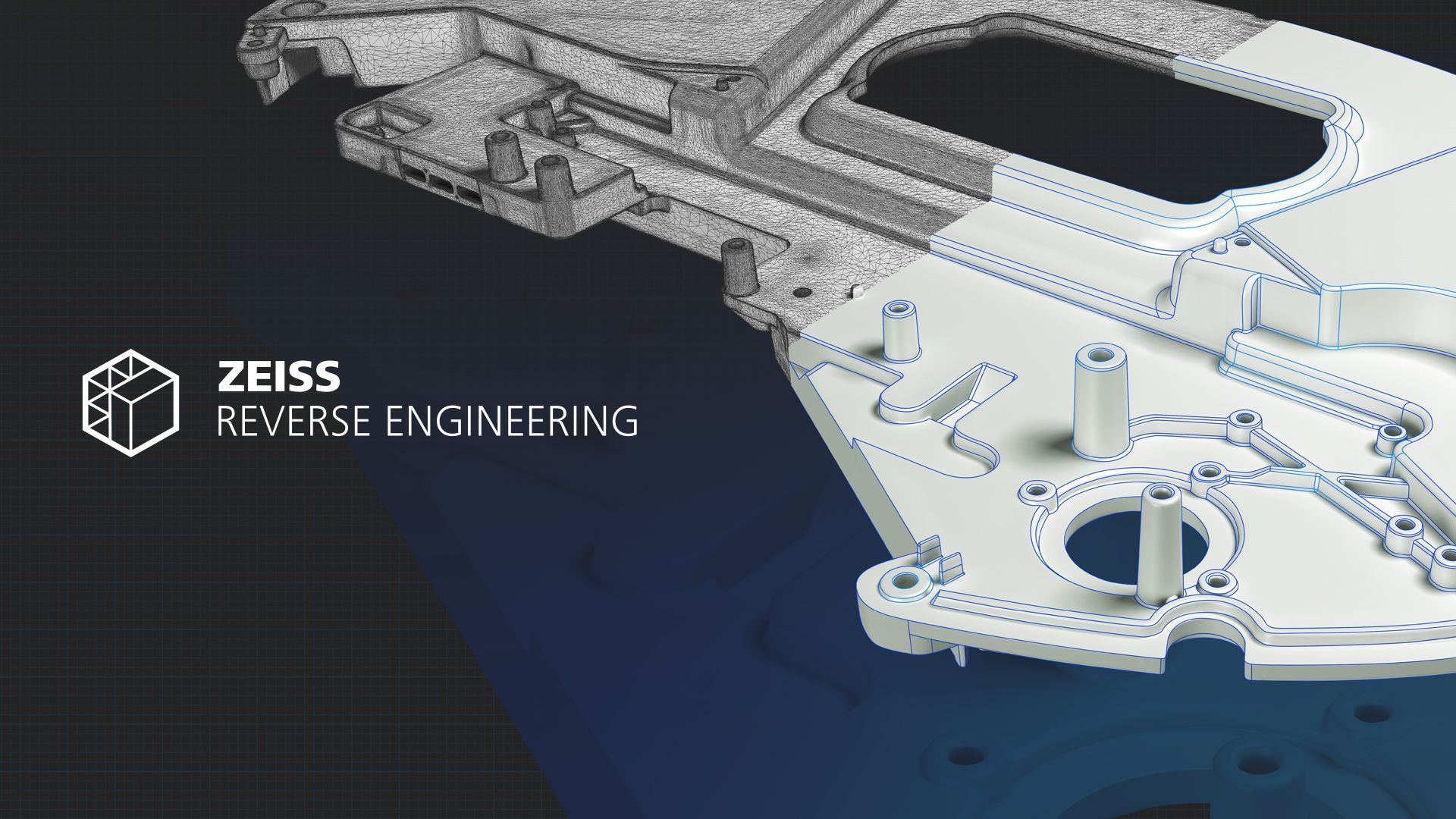

Reverse engineering complex parts used to be slow, risky, and expensive. When geometries are complicated, manual measurement often falls short — resulting in assumptions, errors, and time-consuming rework. 3D scanning changes the game. Modern structured-light and laser scanners capture millions of data points in minutes, producing a full, accurate 3D mesh. That mesh can be turned into CAD, giving you a reliable digital twin — faster, more precisely, and more affordably than older methods. Why Traditional Reverse Engineering Limits Efficiency Relying on manual measurement introduces guesswork. Critical features may be missed. Assumptions lead to mismatches. And when parts need to be reworked, delays and waste accumulate. Legacy parts make this worse. Without current CAD or accurate documentation, recreating a component becomes a guessing game — and those risks eat into your timeline and budget. NIST’s Manufacturing Cost Guide highlights how poorly understood or measured parts can drive up costs. NIST+1 3D Scanning Accelerates Project Timelines Scanning drastically reduces time. In a recent medical-device project, a highly curved housing was scanned in under 10 minutes , generating a dense mesh. Reconstructing it in CAD took less than four hours — versus days under traditional approaches. Speed matters. McKinsey’s analysis of industrial innovation demonstrates how accelerating product development can slash time to market and cut cost. McKinsey & Company Micron-Level Accuracy Reduces Errors Quality matters just as much as speed. Metrology-grade scanners commonly reach 5–20 µm accuracy , capturing critical detail with confidence. In one aerospace application, a scanned bracket revealed deviations of just 0.018 mm . That level of precision means fewer design errors, less rework, and a cleaner handoff to downstream teams. Capture Every Surface — Nothing Gets Missed 3D scanning doesn’t stop at simple shapes. You get every curve, hole, fillet, and freeform surface. This full-surface capture avoids blind spots and unknowns. A real-world example: an automotive die that had been modified over several production runs was scanned. The mesh exposed 0.23 mm of variation across critical surfaces — a key insight that explained recurring assembly failures. Perfect Solution for Legacy Components Reverse engineering legacy parts is where scanning shines: No CAD? No problem. Tooling outdated? We can digitally recreate it. Supplier gone? We still have the geometry. In one aerospace project, a legacy hydraulic valve housing was scanned and reconstructed in under six hours , saving the week or more that traditional methods would have taken. Cost Savings from Speed + Accuracy When you reduce rework, scrap, and iteration, you save real money. According to NIST’s advanced manufacturing research, defects and scrap account for tens of billions of dollars in losses. NIST Publications+1 By shortening reverse engineering cycles and improving precision, 3D scanning can reduce costs by 40–70% , depending on part complexity and project scope. The Real Value: Outsource to Experts Buying a scanner isn’t always the best path. What brings value is expertise — knowing how to align scans, mesh them, reconstruct in CAD, and validate the results. Using a specialized scanning provider means you get: Traceable, high-precision models CAD-ready deliverables Proper scanning and post-processing workflows Fast, predictable turnaround This way, you avoid investing in equipment, training, trial-and-error, and maintenance. Conclusion: Scanning Isn’t Optional — It’s Fundamental 3D scanning is more than a tool. It’s a foundational technology that transforms reverse engineering. With it, you get: Rapid data capture Micron-level precision Full-surface fidelity Faster iterations Lower costs and less scrap If your team is ready to reverse engineer with confidence, fill out the Contact Us form on our website. A 3D scanning specialist will reach out with a scoped quote and guide you through how our process can save you time and money. References: NIST Manufacturing Cost Guide — estimates on cost categories in manufacturing. NIST McKinsey on accelerating product development: “Accelerating product development: The tools you need now.” McKinsey & Company NIST Advanced Manufacturing Series: cost of defects and losses. NIST Publications+1

Introduction If you’re asking, what is 3D scanning, you’re not alone. Engineers in medical devices, aerospace, and automotive are discovering that 3D scanning isn’t just a tech buzzword—it’s a tool that can save hours, reduce errors, and give you a complete picture of your parts. After 5 years working hands-on with 3D scanning systems, I’ve seen how a properly implemented workflow can transform inspection and reverse engineering. In this guide, I’ll break down how 3D scanning works, what types of scanners are available, and why accuracy matters—without getting lost in jargon. Think of this as your engineer-to-engineer briefing. 1. What is 3D Scanning? Imagine trying to measure a complex part with calipers—you’d spend hours, and you’d probably miss small features. That’s where 3D scanning comes in. It captures the shape, size, and surface features of a physical object and turns them into a digital 3D model. 3D scanning explained simply: instead of picking a few points, it measures millions. The result is a highly detailed map of your part that you can inspect, reverse engineer, or simulate digitally. 2. How Does 3D Scanning Work? The 3D scanning process steps are straightforward but critical: Preparation: Clean the part and set it up to reduce measurement errors. Capture: Use a scanner—laser, structured light, or photogrammetry—to record the surface. Processing: Align scans, build a mesh, and correct deviations. Analysis: Compare the 3D model to your CAD designs or nominal specs. Think of it like creating a digital twin of your part. Once it exists virtually, you can check dimensions, test fits, or spot defects—all without touching the original piece. 3. Types of 3D Scanners Not all scanners are created equal. Understanding types of 3D scanners helps you pick the right one for your workflow: Structured Light Scanners: Project light patterns onto the part and measure distortions. Great for small to medium, detailed parts. Laser Scanners: Use laser lines or dots to capture surfaces. Perfect for larger or complex geometries. Photogrammetry: Combines multiple photos to create a 3D model. Handy for large objects or field measurements. Portable vs Fixed Systems: Portable scanners go wherever your parts are; fixed scanners give maximum lab precision. 4. 3D Scanner Accuracy Explained Accuracy is everything. What is 3D measurement accuracy? It’s how closely your scanned data matches reality. Accuracy depends on scanner type, part size, surface finish, and calibration. Repeatability ensures consistent measurements over time. Standards like VDI 2634 provide traceable, reliable results. 5. Benefits of 3D Scanning The benefits of 3D scanning go far beyond speed: Rapid inspection: Full part geometry in minutes, not hours. Data-rich models: Millions of points for thorough analysis. Reverse engineering: Quickly recreate CAD models from existing parts. Non-contact measurement: Perfect for delicate or complex surfaces. 6. Use Cases in Manufacturing Seeing 3D scanning in action helps illustrate value: Aerospace: Inspect turbine blades and structural components with micron-level precision. Medical Devices: Verify implants and surgical tools meet strict standards. Automotive: Reverse-engineer legacy parts or prototype new designs. 7. Getting Started with 3D Scanning If you’re thinking about adding 3D scanning: Start small with simple parts. Build workflows and verify results against standards. Train your team on scanning techniques and data interpretation. Even a small setup pays off: faster inspections, fewer errors, and better understanding of your products. Conclusion 3D scanning isn’t just technical jargon—it’s a practical tool for engineers. By understanding types of 3D scanners and mastering 3D scanning process steps, you can improve inspection speed, accuracy, and insight. Explore our posts on structured light vs laser scanning or 3D scanning for inspection, or contact us for a demo to see it in action. Sources Used in Creating This Content National Institute of Standards and Technology (NIST): Dimensional Metrology Overview National Physical Laboratory (NPL): Metrology and 3D Measurement MDPI Journal: Advances in Optical 3D Scanning and Measurement Systems